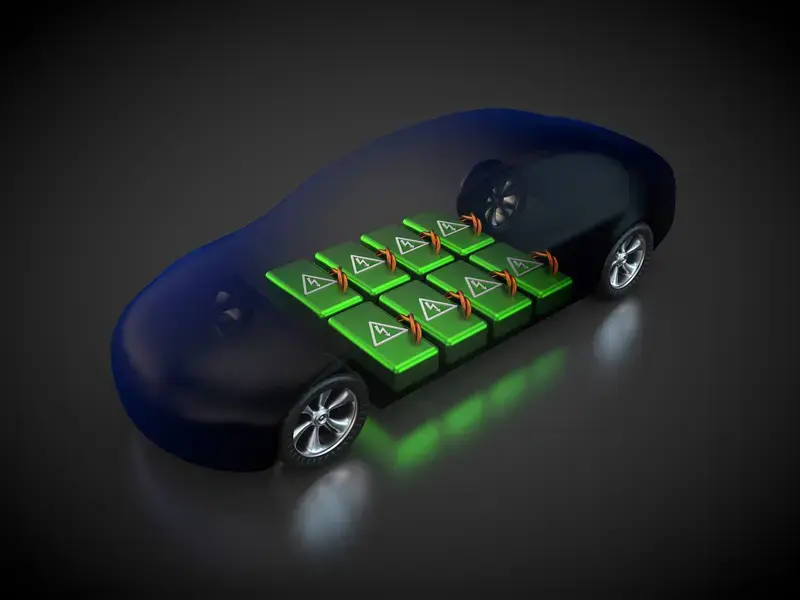

Lithium-ion batteries are powerful – but thermally sensitive. Precise pressure measurement is key to preventing overheating and optimizing cooling systems.

Whether it's exploding laptops or burning electric vehicles – thermal runaway of lithium-ion batteries can have dramatic consequences. This instability often results from overloading or high ambient temperatures and occurs in several dangerous stages:

- from 80 °C: Dissolution of the SEI layer, initial exothermic reactions

- from 110 °C: Decomposition of organic solvents, gas formation, pressure increase

- from 135 °C: Melting of separator foil → short circuit

- from 200 °C: Decomposition of cathode, oxygen release, ignition

Thermal management through liquid cooling

To control these risks, modern EV batteries use liquid-cooled systems. Coolers and BMS (Battery Management System) regulate temperature and heat dissipation.

Designing these systems requires sound data: temperature and pressure measurements during charge and discharge cycles form the basis. Only then can cooling channels be dimensioned and simulations set up – for example with software like PTC CreoParametric 3D.

Why pressure measurement is crucial

Optimal heat transfer depends on the interplay of coolant flow, temperature, and pressure. A pressure difference of just 0.008 bar between inlet and outlet can be decisive – demanding highest precision in pressure measurement.

Sensors like the ATM.1ST from STS meet these requirements. They offer:

- Very high measurement accuracy at low differential pressures

- Long-term stability over broad temperature ranges

- Compact, media-resistant design for contact with liquids

Engineers use this data to compare pressure losses along various channel designs – visually represented in curves for minimal and maximum flow rates. The Bernoulli equation shows: Higher flow rate = quadratically increasing pressure loss.

Design optimization through measurement data

For this reason, developers adopt wider cooling channels with multiple passages to improve heat dissipation via forced convection. The result: more stable cell temperatures, reduced risk of thermal runaway, and higher cycle life.

Conclusion

Accurate pressure measurement makes an essential contribution to the safety and efficiency of lithium-ion batteries – especially during development. Sensors like the ATM.1ST from STS enable optimization of cooling concepts, reduction of risks, and long-term system performance security.